1 Gadzirira ungano isati yasvika

1.1Ita shuwa kuti iyo flange yekubatanidza yakasarudzwa se ISO 6162-1 inosangana nezvinodiwa zvechishandiso (semuenzaniso yakayerwa kudzvanywa, tembiricha nezvimwewo).

1.2Ita shuwa kuti zvinhu zveflange (flange chinongedzo, simbi, screw, O-mhete) uye zviteshi zvinoenderana ne ISO 6162-1.

1.3Ita shuwa kuti akakodzera screws, metric yerudzi rwekutanga uye inch yerudzi rwechipiri.

1.4Ita shuwa kuti hausanganise zvikamu ne ISO 6162-2 zvikamu.Nzira yekuziva sei zvakasiyana siyana"Maitiro ekuziva ISO 6162-1 uye ISO 6162-2 flange kubatana uye zvikamu"link.

1.5Ita shuwa kuti yese yekuisa chisimbiso uye yepasi interface (inosanganisira port uye flange zvikamu) hazvina maburrs, nick, makwara uye chero zvinhu zvekunze.

2 Nzira yekuunganidza zvakanaka

2.1Kuti ubatsire kuderedza O-ring scrub-out, gadzira O-ring nejasi rakareruka re hydraulic fluid inoshandiswa muhurongwa kana mafuta anowirirana, kana zvichidiwa.Chengetedza zvakanyanya, sezvo mafuta akawandisa anogona kubuda kubva mujoini uye achitungamira kune chiratidzo chenhema chekudonha.

Cherechedza:O-mhete saizi ona tafura 1 kana tafura 2, uye yakafanana saizi yemetric kana inch screw, yakakura saizi ye ISO 6162-1 uye ISO 6162-2 flange yekubatanidza, hapana nyaya yakasanganiswa.

2.2Isa musoro wakafuratira uye mabhanhire eflange.

2.3Isai mawashi akaomeswa pazvisungo, uye isa zvisungo kuburikidza nemakomba ari mumagetsi.

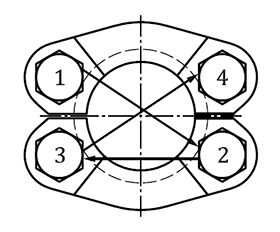

2.4Ruoko simbisa masiruru mukutevedzana kunoratidzwa muFigure 1 kuve nechokwadi chekubata yunifomu pane ese mana screw nzvimbo kudzivirira iyo flange tipping, izvo zvinogona kutungamirira kune flange kutyoka panguva yekushandisa yekupedzisira torque.

Mufananidzo 1 - Screw tightening kutevedzana

2.5Torque ma screws munhevedzano inoratidzwa muMufananidzo 1 mukuwedzera kuviri kana kudarika kune inokurudzirwa screw torque level uye kushandisa masikuru anoenderana netafura 1 yemetric screw uye tafura 2 ye inch screw.

Tafura 1 - Torque uye wrench saizi ine metric screw yekuunganidza maflange ekubatanidza anoenderana ne ISO 6162-1.

| Nominal saizi | Maximum kushanda pressure | Type 1 (metric) | ||||||||

| Screw Thread | Kureba kwekukwenya mm | Screw torque N.m | Chipanera | O-mhete | ||||||

| MPa | bar | nokuda kwehexagon musoro sikuruu mm | for socket musoro sikuruu mm | Code | Ipasi dhayamita mm | Crosi -chikamu mm | ||||

| 13 | 35 | 350 | M8 | 25 | 32 | 13 | 6 | 210 | 18.64 | 3.53 |

| 19 | 35 | 350 | M10 | 30 | 70 | 16 | 8 | 214 | 24.99 | 3.53 |

| 25 | 32 | 320 | M10 | 30 | 70 | 16 | 8 | 219 | 32.92 | 3.53 |

| 32 | 28 | 280 | M10 | 30 | 70 | 16 | 8 | 222 | 37.69 | 3.53 |

| 38 | 21 | 210 | M12 | 35 | 130 | 18 | 10 | 225 | 47.22 | 3.53 |

| 51 | 21 | 210 | M12 | 35 | 130 | 18 | 10 | 228 | 56.74 | 3.53 |

| 64 | 17.5 | 175 | M12 | 40 | 130 | 18 | 10 | 232 | 69.44 | 3.53 |

| 76 | 16 | 160 | M16 | 50 | 295 | 24 | 14 | 237 | 85.32 | 3.53 |

| 89 | 3.5 | 35 | M16 | 50 | 295 | 24 | 14 | 241 | 98.02 | 3.53 |

| 102 | 3.5 | 35 | M16 | 50 | 295 | 24 | 14 | 245 | 110.72 | 3.53 |

| 127 | 3.5 | 35 | M16 | 55 | 295 | 24 | 14 | 253 | 136.12 | 3.53 |

Tafura 2 - Torque uye wrench saizi ine inch screw yekuunganidza flange zvinongedzo zvinoenderana ne ISO 6162-1

| Nominal saizi | Maximum kushanda pressure | Type 2 (inch) | ||||||||

| Screw Thread | Kureba kwekukwenya mm | Screw torque N.m | Chipanera | O-mhete | ||||||

| MPa | bar | nokuda kwehexagon musoro sikuruu in | for socket musoro sikuruu in | Code | Ipasi dhayamita mm | Crosi -chikamu mm | ||||

| 13 | 35 | 350 | 5/16-18 | 32 | 32 | 1/2 | 1/4 | 210 | 18.64 | 3.53 |

| 19 | 35 | 350 | 3/8-16 | 32 | 60 | 9/16 | 5/16 | 214 | 24.99 | 3.53 |

| 25 | 32 | 320 | 3/8-16 | 32 | 60 | 9/16 | 5/16 | 219 | 32.92 | 3.53 |

| 32 | 28 | 280 | 7/16-14 | 38 | 92 | 5/8 | 3/8 | 222 | 37.69 | 3.53 |

| 38 | 21 | 210 | 1/2-13 | 38 | 150 | 3/4 | 3/8 | 225 | 47.22 | 3.53 |

| 51 | 21 | 210 | 1/2-13 | 38 | 150 | 3/4 | 3/8 | 228 | 56.74 | 3.53 |

| 64 | 17.5 | 175 | 1/2-13 | 44 | 150 | 3/4 | 3/8 | 232 | 69.44 | 3.53 |

| 76 | 16 | 160 | 5/8-11 | 44 | 295 | 15/16 | 1/2 | 237 | 85.32 | 3.53 |

| 89 | 3.5 | 35 | 5/8-11 | 51 | 295 | 15/16 | 1/2 | 241 | 98.02 | 3.53 |

| 102 | 3.5 | 35 | 5/8-11 | 51 | 295 | 15/16 | 1/2 | 245 | 110.72 | 3.53 |

| 127 | 3.5 | 35 | 5/8-11 | 57 | 295 | 15/16 | 1/2 | 253 | 136.12 | 3.53 |

Nguva yekutumira: Jan-20-2022